Kev siv hauv kev lag luam semiconductor

GREEN yog National High-Tech Enterprise mob siab rau R & D thiab tsim cov khoom siv hluav taws xob siv hluav taws xob sib dhos thiab cov khoom ntim semiconductor & kuaj cov khoom. Pab cov thawj coj hauv kev lag luam xws li BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, thiab 20+ lwm lub tuam txhab Fortune Global 500. Koj tus khub ntseeg siab rau cov kev tsim khoom siab heev.

Bonding tshuab pab kom micro-interconnects nrog hlau diameters, kom ntseeg tau cov teeb liab kev ncaj ncees; formic acid nqus tsev soldering cov ntaub ntawv txhim khu kev qha pob qij txha nyob rau hauv cov ntsiab lus oxygen <10ppm, tiv thaiv oxidation tsis ua hauj lwm nyob rau hauv high-density ntim; AOI cuam tshuam qhov tsis xws luag hauv micron. Qhov kev sib koom ua ke no ua kom ntseeg tau> 99.95% cov khoom ntim siab tshaj plaws, ua tau raws li qhov kev sim siab xav tau ntawm 5G / AI chips.

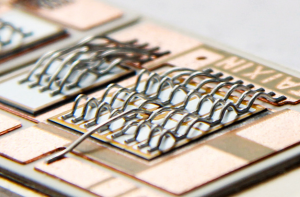

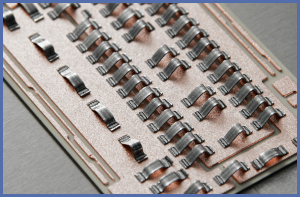

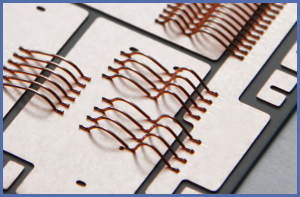

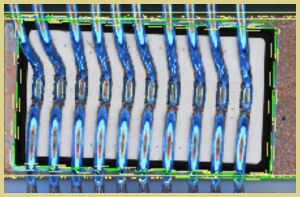

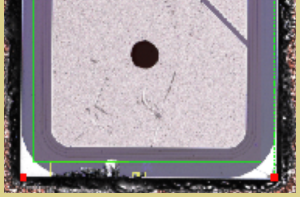

Ultrasonic Hlau Bonder

Muaj peev xwm ntawm kev sib txuas ntawm 100 μm-500 μm txhuas hlau, 200 μm-500 μm tooj liab hlau, txhuas ribbons txog 2000 μm dav thiab 300 μm tuab, nrog rau tooj liab ribbons.

Kev mus txawv tebchaws: 300 mm × 300 mm, 300 mm × 800 mm (customizable), nrog repeatability < ± 3 μm

Kev mus txawv tebchaws: 100 mm × 100 mm, nrog repeatability < ± 3 μm

Dab tsi yog Hlau Bonding Technology?

Hlau bonding yog cov txheej txheem kev sib txuas ntawm microelectronic siv los txuas cov khoom siv semiconductor rau lawv cov ntim lossis cov substrates. Raws li ib qho ntawm cov thev naus laus zis tseem ceeb tshaj plaws hauv kev lag luam semiconductor, nws ua rau cov nti cuam tshuam nrog cov hluav taws xob sab nraud hauv cov khoom siv hluav taws xob.

Cov khoom siv hlau nplaum

1. Aluminium (Al)

Superior hluav taws xob conductivity vs. kub, nqi-zoo

2. Copper (Cu)

25% siab dua hluav taws xob / thermal conductivity tshaj Au

3. Kub (Au)

Optimal conductivity, corrosion kuj, thiab kev ntseeg tau ntawm kev sib koom ua ke

4. Nyiaj (Ag)

Cov conductivity siab tshaj ntawm cov hlau

Aluminium Hlau

Aluminium Ribbon

Tooj Hlau

Tooj Ribbon

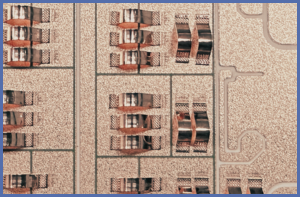

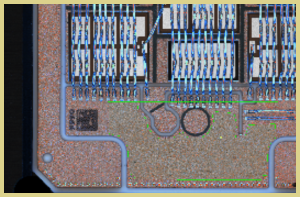

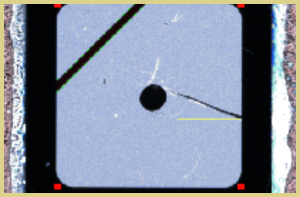

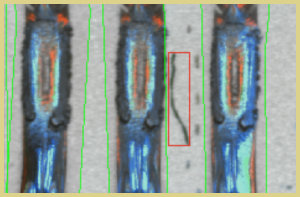

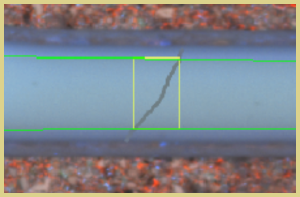

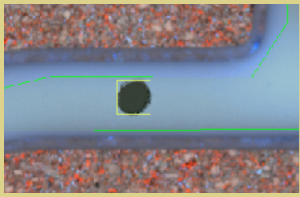

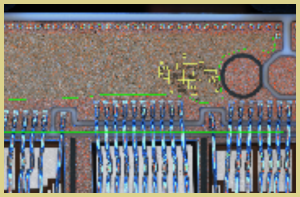

Semiconductor Tuag Bonding & Hlau Bonding AOI

Siv 25-megapixel lub koob yees duab kev lag luam txhawm rau kuaj xyuas qhov tuag txuas thiab xaim kev sib txuas ntawm cov khoom xws li ICs, IGBTs, MOSFETs, thiab cov hlau lead thav duab, ua tiav qhov kev kuaj pom tsis zoo ntau dua 99.9%.

Tshuaj ntsuam xyuas

Muaj peev xwm ntawm kev tshuaj xyuas nti qhov siab thiab flatness, nti offset, qaij, thiab chipping; solder pob tsis-adhesion thiab solder sib koom detachment; kev sib txuas ntawm cov hlau tsis xws li lub voj voog ntau dhau lossis tsis txaus, lub voj voj voog, cov xov hlau tawg, cov xov hlau uas ploj lawm, cov xov hlau sib txuas, xov hlau khoov, lub voj hla, thiab qhov ntev ntev; adhesive tsis txaus; thiab hlau splatter.

Solder Pob / Residue

Chip Scratch

Chip Placement, Dimension, Tilt Meas

Chip Contamination / Cov khoom txawv teb chaws

Chip Chip

Ceramic Trench Cracks

Ceramic Trench Contamination

Oxidation ntawm AMB

In-Line Formic Acid Reflow Cub

1. Qhov siab tshaj plaws kub ≥ 450 ° C, lub tshuab nqus tsev tsawg kawg < 5 Pa

2. Txhawb formic acid thiab nitrogen txheej txheem ib puag ncig

3. Ib leeg-point void tus nqi ≦ 1%, tag nrho void tus nqi ≦ 2%

4. Dej txias + nitrogen txias, nruab nrog cov dej txias thiab tiv tauj cua txias

IGBT Lub Zog Semiconductor

Cov nqi voiding ntau dhau hauv IGBT soldering tuaj yeem ua rau cov saw hlau tsis ua haujlwm nrog rau cov thermal khiav, kev sib tsoo, thiab hluav taws xob ua haujlwm tsis zoo. Txo qhov tsis muaj nqi rau ≤1% ua rau muaj txiaj ntsig zoo ntawm cov cuab yeej kev ntseeg siab thiab lub zog ua haujlwm.

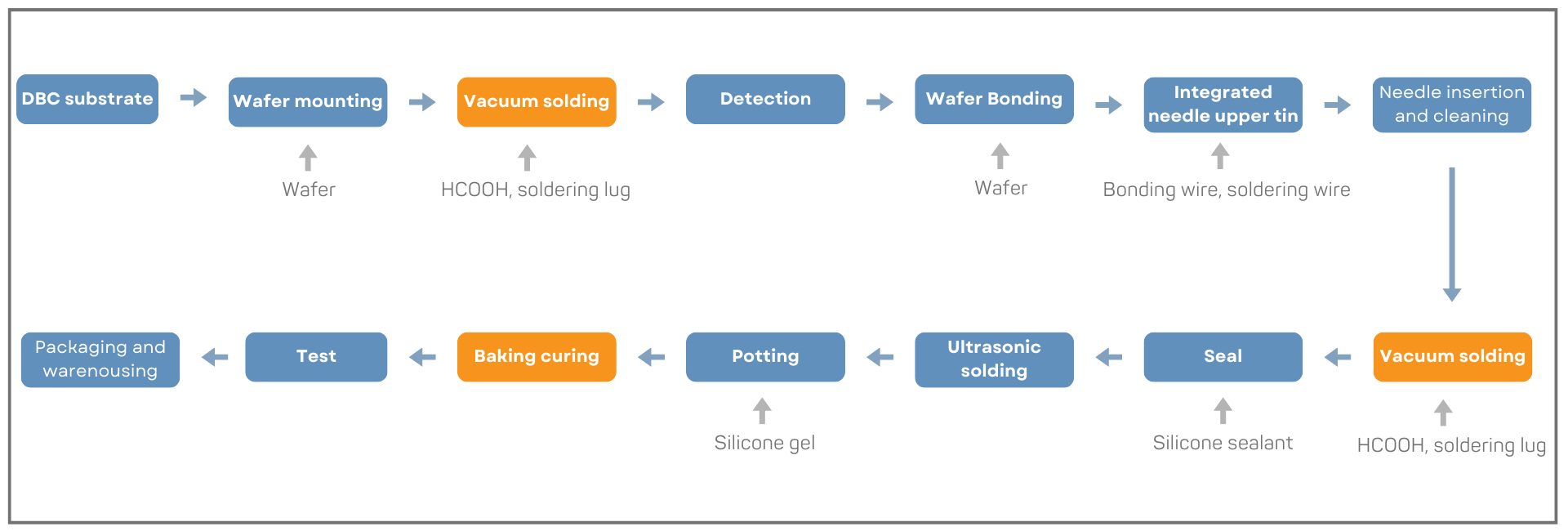

IGBT Production process flowchart