Daim ntawv thov ntawm SMT back-end cell kab hauv 3C electronics kev lag luam

GREEN yog National High-Tech Enterprise mob siab rau R & D thiab tsim cov khoom siv hluav taws xob siv hluav taws xob sib dhos thiab cov khoom ntim semiconductor & kuaj cov khoom.

Pab cov thawj coj hauv kev lag luam xws li BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, thiab 20+ lwm lub tuam txhab Fortune Global 500. Koj tus khub ntseeg siab rau cov kev tsim khoom siab heev.

Surface Mount Technology (SMT) yog cov txheej txheem tseem ceeb hauv kev tsim khoom siv hluav taws xob niaj hnub, tshwj xeeb tshaj yog rau kev lag luam 3C (lub computer, kev sib txuas lus, khoom siv hluav taws xob). Nws mounts leadless/short-lead Cheebtsam (SMDs) ncaj qha mus rau PCB nto, enabling high-density, miniaturized, hnav, high-reliability, thiab high-efficiency ntau lawm.Yuav ua li cas SMT kab siv nyob rau hauv lub 3C electronics kev lag luam, thiab cov khoom tseem ceeb thiab txheej txheem theem nyob rau hauv SMT back-end cell kab.

□ 3C cov khoom siv hluav taws xob (xws li smartphones, ntsiav tshuaj, laptops, smartwatches, headphones, routers, thiab lwm yam) xav tau kev ua haujlwm siab me me, slim profiles, kev ua haujlwm siab,thiab ceev ceev

iteration.SMT kab ua haujlwm ua lub hauv paus tsim khoom lag luam uas ua raws li cov kev xav tau no.

□ Kev Ua Tau Zoo Heev Miniaturization thiab Lightweighting:

SMT ua kom muaj qhov ntom ntom ntawm cov khoom siv micro (piv txwv li, 0201, 01005, lossis me dua resistors / capacitors; nplua-pitch BGA / CSP chips) ntawm PCBs, txo qhov hluav taws xob hauv Circuit Court.

hneev taw, tag nrho cov khoom ntim, thiab qhov hnyav - ib qho tseem ceeb rau cov khoom siv nqa tau zoo li smartphones.

□ Enabling High-Density Interconnect & High Performance:

Cov khoom lag luam 3C niaj hnub xav tau kev ua haujlwm nyuaj, yuav tsum muaj kev sib txuas siab siab (HDI) PCBs thiab ntau txheej txheej txheej txheej. SMT qhov kev tso kawm muaj peev xwm ua tau zoo

lub hauv paus rau txhim khu kev qha kev sib txuas ntawm high-density thaiv thiab cov chips siab heev (piv txwv li, processors, nco modules, RF units), kom ntseeg tau tias cov khoom ua tau zoo.

□ Boosting Production Efficiency & Txo cov nqi:

SMT kab xa cov automation siab (luam ntawv, tso, reflow, soj ntsuam), ultra-ceev throughput (xws li, qhov chaw tso kawm ntawv tshaj 100,000 CPH), thiab tsawg heev phau ntawv cuam tshuam. Qhov no

Ua kom muaj qhov sib xws tshwj xeeb, cov txiaj ntsig siab tshaj plaws, thiab txo qis tus nqi ntawm ib chav tsev hauv kev tsim khoom loj-zoo tag nrho nrog 3C cov khoom xav tau rau lub sijhawm sai-rau-kev ua lag luam thiab

kev sib tw nqi.

□ Ua kom cov khoom ntseeg tau & Zoo:

Cov txheej txheem SMT Advanced-xws li kev luam ntawv precision, kev tso kawm siab, kev tswj xyuas reflow profileing, thiab kev soj ntsuam nruj inline - lav kev sib koom ua ke thiab

kev ntseeg tau. Qhov no txo qis qhov tsis xws luag xws li cov pob qij txha txias, kev sib txuas, thiab cov khoom tsis sib haum, ua tau raws li 3C cov khoom 'kev ua haujlwm ruaj khov uas yuav tsum tau ua hauv hnyav.

ib puag ncig (xws li kev vibration, thermal cycling).

□ Adapting rau Rapid Product Iteration:

Kev sib koom ua ke ntawm Flexible Manufacturing System (FMS) cov hauv paus ntsiab lus ua rau SMT kab kom hloov pauv sai ntawm cov qauv khoom, dynamically teb rau kev hloov pauv sai.

xav tau ntawm 3C lag luam.

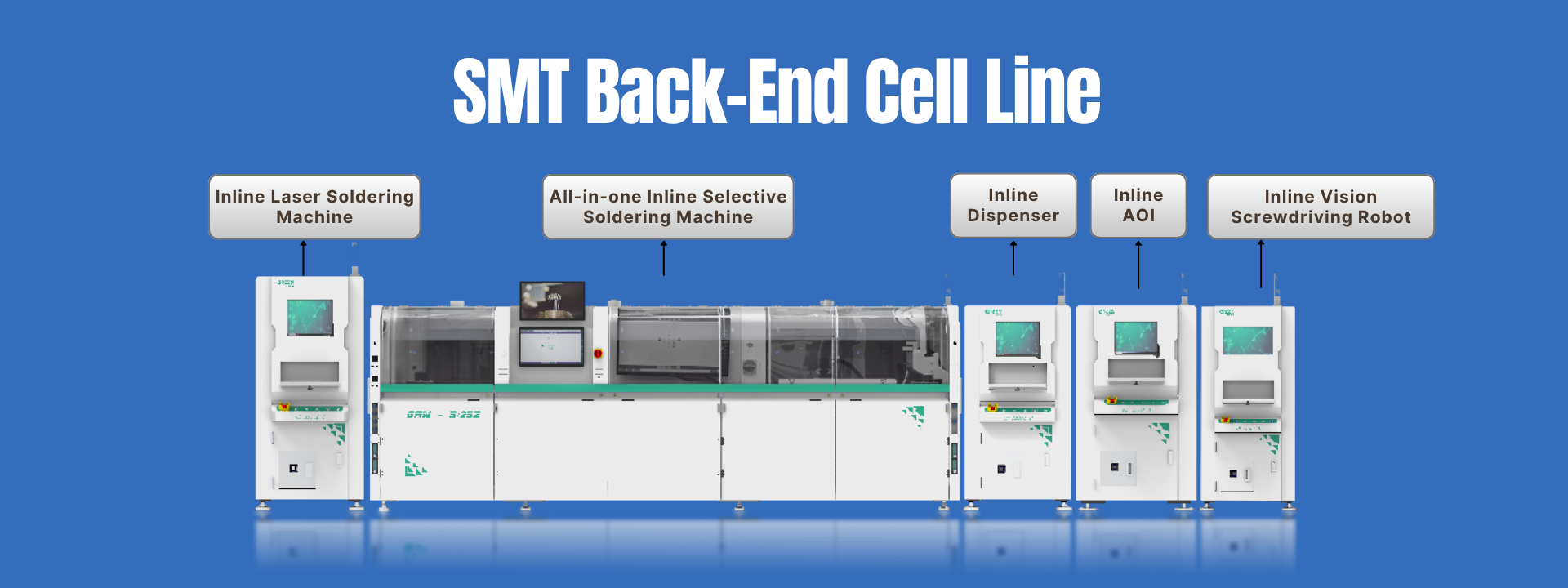

Laser Soldering

Pab kom precision kub-tswj soldering los tiv thaiv kev puas tsuaj rau cov khoom siv thermosensitive. Siv cov txheej txheem tsis sib cuag uas tshem tawm cov kev ntxhov siab, tsis txhob cuam tshuam los yog PCB deformation - optimized rau qhov nkhaus / tsis zoo.

Xaiv Wave Soldering

Populated PCBs nkag mus rau hauv qhov cub reflow, qhov twg qhov kev tswj xyuas qhov kub thiab txias (preheating, soaking, reflow, txias) melts lub solder paste. Qhov no ua rau cov ntaub ntub dej ntawm cov ntaub qhwv thiab cov khoom ua haujlwm, tsim cov khoom lag luam txhim khu kev qha (cov pob qij txha), ua raws li kev ua kom tiav thaum txias. Kev tswj qhov kub thiab txias yog qhov tseem ceeb tshaj plaws rau kev siv vuam zoo thiab kev ntseeg tau ntev.

Full-Automatic High-Speed In-Line Dispensing

Populated PCBs nkag mus rau hauv qhov cub reflow, qhov twg qhov kev tswj xyuas qhov kub thiab txias (preheating, soaking, reflow, txias) melts lub solder paste. Qhov no ua rau cov ntaub ntub dej ntawm cov ntaub qhwv thiab cov khoom ua haujlwm, tsim cov khoom lag luam txhim khu kev qha (cov pob qij txha), ua raws li kev ua kom tiav thaum txias. Kev tswj qhov kub thiab txias yog qhov tseem ceeb tshaj plaws rau kev siv vuam zoo thiab kev ntseeg tau ntev.

AOI tshuab

Post-Reflow AOI Kev Tshawb Fawb:

Tom qab reflow soldering, AOI (Automated Optical Inspection) tshuab siv lub koob yees duab daws teeb meem thiab cov duab ua software kom tau txais kev tshuaj xyuas cov khoom sib koom ua ke ntawm PCBs.

Qhov no suav nrog kev txheeb xyuas qhov tsis xws luag xws li:Solder Defects: Tsis txaus / dhau solder, txias pob qij txha, bridging.Cheebtsam Defects: misalignment, uas ploj lawm Cheebtsam, tsis ncaj ncees lawm qhov chaw, rov qab polarity, tombstoning.

Raws li qhov tseem ceeb ntawm kev tswj hwm qhov zoo hauv SMT kab, AOI ua kom muaj kev ncaj ncees.

Vision-Guided Inline Screwing Tshuab

Tsis pub dhau SMT (Surface Mount Technology) kab, qhov system no ua haujlwm raws li cov khoom siv tom qab sib dhos, ruaj cov khoom loj lossis cov txheej txheem ntawm PCBs-xws li cov dab dej kub, cov khoom sib txuas, cov khoom siv hauv tsev, thiab lwm yam.